Advent of the Green Retarder

Over the last five years, the Green Retarder has been developed to the same exacting standards as the VH Retarder, in answer to the challenge of new, friendlier Ecology requirements in international law, and tested over 10 000 hours and 50 000 wagon transfers. Other significant improvements have been brought to the Green Retarder, in the following regards:

- Fewer moving parts

- Less maintenance

- Each unit can be individually adjusted

- The unit operates on Pneumatics, not Hydraulics

- The system can be integrated electronically with the Signal System and remotely controlled.

- The System can be deployed on an ad hoc basis, as opposed to full-time deployment.

- The piston is in the default down position, not default up, resulting in substantially less wear and tear during idling on both the Retarders and the Wagon Wheels.

The Green Retarder is manufactured to ISO 9000 and ISO 14000 standards, using only rolled or forged high quality carbon grade steel, with all precision machining, using CNC machines, purpose engineered for this product. The product is manufactured and exclusively developed for the railroad, and marketed internationally by Gravity Engineering.

RETARDER FUNCTIONS

- The retarders are designed to hold trucks once uncoupled from the locomotive.The retarders are able to slow down trucks entering in a controlled area

- The retarders are environmentally friendly.

- No oil activated retarders are installed to prevent contamination.

- The retarders are activated by air pressure or similar. The sealing arrangements can withstand condensation and temperatures up to 70 degrees

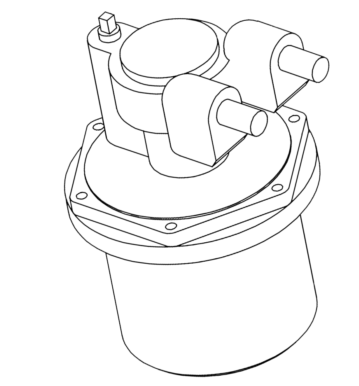

COMPRESSOR INSTALLATION

- The sealing arrangement is of silicon fibre.

- Design the installation is be done by trained technicians.

- The air supply to the retarder pots are supplied by a reciprocating compressor @ Max 16 bar.

- The air supply passes through a Dryer and refrigerator supplying the 16 bar pressure.

- 3,000 hours of services between changes (instead of usual 500).

- Cast iron fan type flywheel pulley.

- Centrifugal unloader to prevent cylinder from starting loaded.

- Dry type 10 inlet filter/silencer.

COMPRESSOR METHODOLOGY

- The compressor switches to unload service when receiver pressure reaches the pre-set pressure}The absorbed power is reduced to about 1/5, with the motor always on.

- The air inlet opens and the compressor reloads when the receiver pressure reaches the pre-set load pressure

- The working pressure can be set while the compressor is working, through the auxiliary Valve

COMPRESSOR CHARACTERISTICS

COMPRESSOR ELECTRICS AND TRANSMISSION

SAFETY FEATURES AND DESIGN TESTING

Compressor characteristics and working conditions:

- Number of stages 2

- Number of cylinders 2

- Rotation speed rpm 1100

- Inlet pressure atmospheric

- Piston displacement l./min. 1720

- Max. working pressure bar.g 16

N.1 Electric motor asynchronous, three phase, 4 poles, TEFC, IP-55, Class F

Insulation:

- Power HP 20.

- Voltage Volt 525.

- Frequency Hz 50.

Belt transmission including:

- Motor pulley.

- Series of V-belts.

- Pressure gauge

- Safety valve

- Manual condensate drain trap

- Ball valve

- Auxiliary valve for CSC regulation

- Automatic water trap

- Design, construction and testing according to CE 87/404, volume l.500, design pressure bar 16.

Avoidable Accidents

Rescue workers search the scene of the Rovos Rail train derailment in Pretoria, South Africa on April 21. The train was carrying tourists on a luxury rail safari went off the tracks Wednesday outside a station in the South African capital, killing two people.

4 locomotives were parked on the spur line next to the main line without any power. A coal train passed at about 4am and the vibration of the passing train set the parked unit into motion. We find it difficult to imagine that locomotives do not have the equivalent of a hand brake, but this seems to be what happened. Because of the slight gradient the locomotives gained momentum and jumped the points onto the main line hitting the rear wagon of the coal train. The results, as they say, are history. This event will quite probably not be a news item, as there were no casualties.